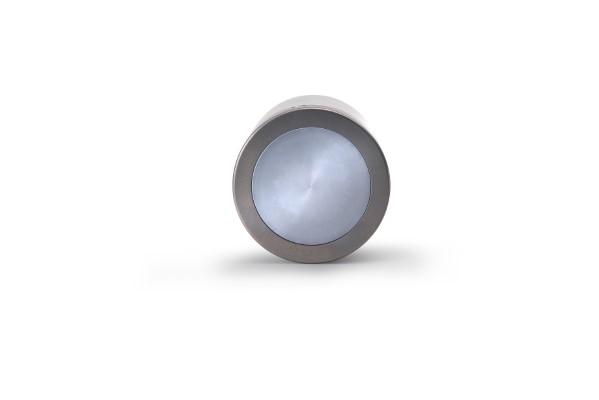

Measurement:

- Moisture

- Ambient temperature

Typical Materials:

- Concrete

- Sand

- Stone

- Other Aggregates

Unique Key Features:

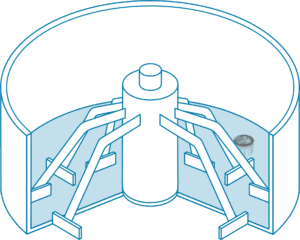

- Rugged, hard-wearing design for abrasive materials.

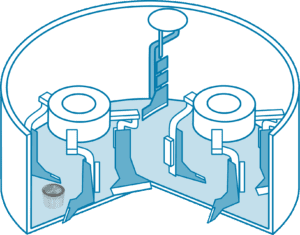

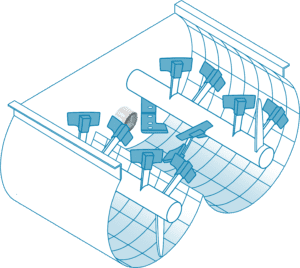

- Simple installation in mixers and conveyors.

- Choice of measurement modes for optimum sensor performance.

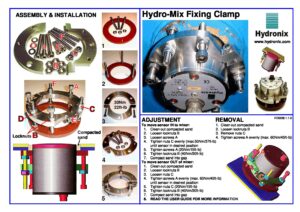

0021 Hydro-Mix – Fixing Plate, Mild Steel

0021 Hydro-Mix – Fixing Plate, Mild Steel 0960 Hydro-Mix – Fixing Plate (316 Stainless Steel)

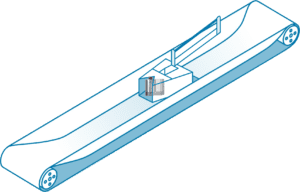

0960 Hydro-Mix – Fixing Plate (316 Stainless Steel) HS02 Hydro-Skid Pantograph Arm for mounting the Hydro-Mix Sensor upon flowing material on a conveyor

HS02 Hydro-Skid Pantograph Arm for mounting the Hydro-Mix Sensor upon flowing material on a conveyor 0033 Hydro-Mix – Adjustable Clamp Ring (spare if required)

0033 Hydro-Mix – Adjustable Clamp Ring (spare if required) 0035 Hydro-Mix Blanking Plate

0035 Hydro-Mix Blanking Plate 0900 Hydro-Mix Replacement Ceramic Disc and Protection Ring Kit (incl. Ceramic Retaining Ring and all fixings)

0900 Hydro-Mix Replacement Ceramic Disc and Protection Ring Kit (incl. Ceramic Retaining Ring and all fixings) 0910 Hydro-Mix Replacement Ceramic Disc and Protection Ring Kit

0910 Hydro-Mix Replacement Ceramic Disc and Protection Ring Kit 0930 Hydro-Mix Replacement Protection Ring, with fixings

0930 Hydro-Mix Replacement Protection Ring, with fixings 0935 Hydro-Mix Replacement Ceramic Retaining Ring Kit (incl. screws, ‘O’ ring and grease)

0935 Hydro-Mix Replacement Ceramic Retaining Ring Kit (incl. screws, ‘O’ ring and grease) 0975A 4m Sensor Cable

0975A 4m Sensor Cable 0975AT Sensor Cable with Network Termination (4, 10, 25 and 50m)

0975AT Sensor Cable with Network Termination (4, 10, 25 and 50m)

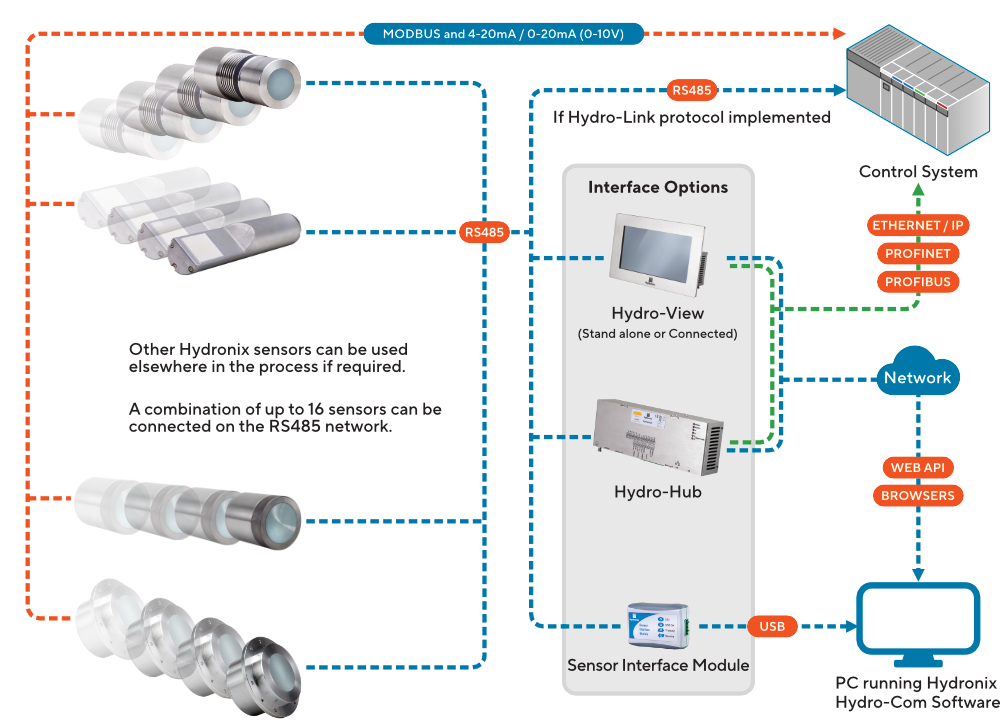

- Digital Technology

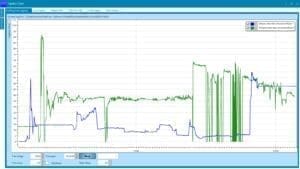

- Digital technology provides precise, linear moisture measurement.

- Advanced Digital Signal Processing

- The sensor response may be adjusted remotely using the Hydro-Com software to minimise the effects of noise of the measured signal. Advanced Digital Signal Processing provides a clear signal with a rapid response.

- Measurement Modes

- Choice of measurement modes for optimising sensor performance in a variety of applications and material types (except Hydro-Probe).

- Fully Temperature Compensated Measurement

- The sensor internally adjusts for mechanical changes due to temperature fluctuations

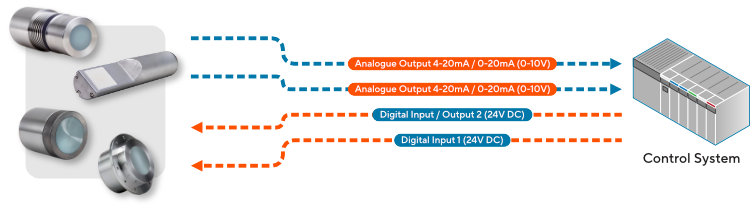

- Easy to Interface

- Two analogue outputs and digital RS485 communications and configurable digital inputs / output make the sensor simple to integrate into a control system. Includes Modbus.

- Fast Measurement

- Measuring at 25 times per second, the sensor continuously detects changes in the moisture of the materials throughout processing.

- Temperature Measurement

- Temperature output is available to provide a readout of material temperature.

- Accuracy of Measurement

- All measurements can be calibrated to an accuracy of 0.2% for aggregates (0.1% in the mixer) and 0.5% for other materials.

- Sensor Configuration

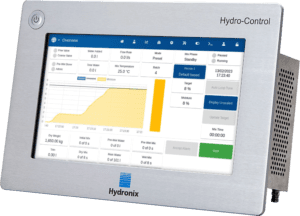

- Sensors can be remotely configured using Hydro-Com diagnostic software or Hydro-View/Hydro-Hub. All readings and sensor parameters are available including the type of output and filtering characteristics.

- Calibration

- The sensor may be internally calibrated using Hydro-Com software, or the linear output may be calibrated within the control system or remotely by using the Hydronix Hydro-View/Hydro-Hub interfaces.

- Simple Power Requirements

- The sensor may be powered from a 15-30V dc supply. Multiple sensors may be driven from a single power source.

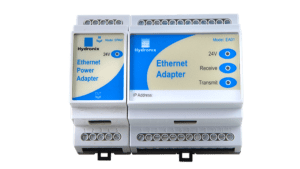

Modbus to control system

Input / Output connections

Recommended field cabling:

- Six pairs twisted (12 cores total) screened (shielded) cable with 22 AWG, 0.35mm2 conductors

- Screen (shield): Braid with 65% minimum coverage plus aluminium/polyester foil

- Recommended cable types: Belden 8306, Alpha 6373

- Maximum cable run: 100m, separate to any heavy equipment power cables