Ready Mix Concrete

Thanks to moisture measurement, ready-mix concrete manufacturers can optimise their mix designs to reduce cement by improving the repeatability of their production. It also allows waste reduction, increasing yield and delivering a consistent final product.

Typical Applications

Typical Materials

- Concrete

- Aggregates

- Sand

- Stones

- Other aggregates

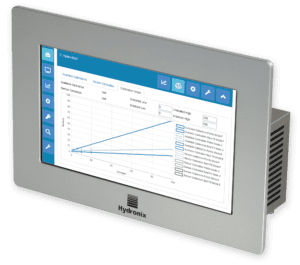

Process Control

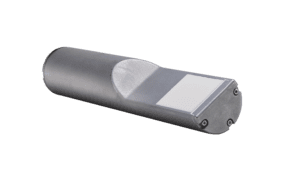

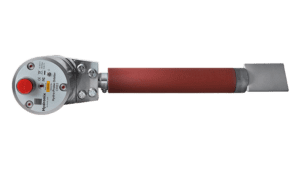

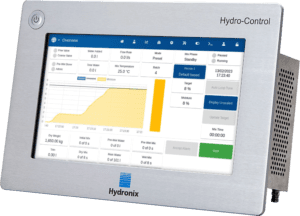

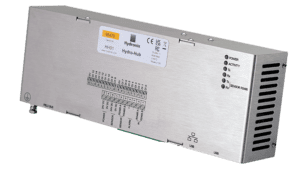

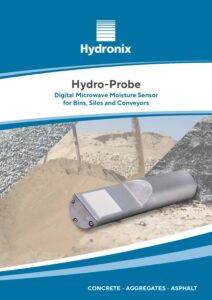

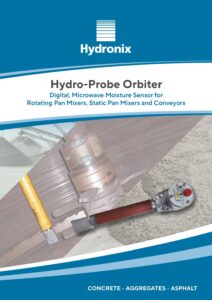

Related Products

Product Overview

CONTROLLING MOISTURE IN CONCRETE BATCHING

This video provides an overview of the Hydronix product range specifically designed for the concrete & construction industry.

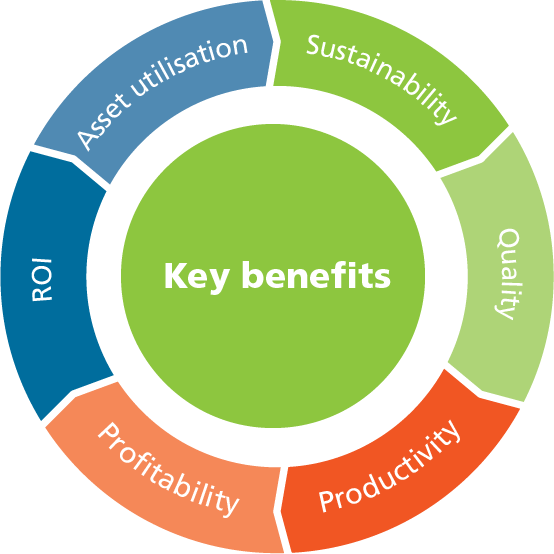

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Moisture Measurement – an Essential for Automating Concrete Production

The current worldwide health challenges are causing many organisations to adjust their working practices to minimise the staff involved in a site whilst still managing full production schedules. Automation is…

Read more

Capturing and using moisture measurement data: ‘Big Moisture’

For many industries, measurement and control of the moisture in materials is vital. Whether it be adding the incorrect amount of water spoils the product or over-drying it wastes energy,…

Read more