Measurement:

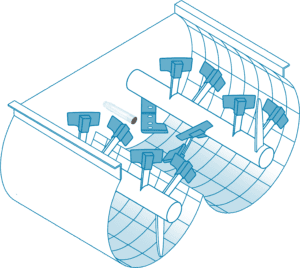

- Batch Temperature

Typical Materials:

- Sand

- Cement

- Concrete

- Asphalt

- Aggregates

Unique Key Features:

- Rugged, hard-wearing design for abrasive materials.

- Choice of fixing option for easy installation.

- Temperature range from 0°C up to 80°C.

Processes

- Digital Technology

- Digital technology provides precise, linear moisture measurement.

- Advanced Digital Signal Processing

- The sensor response may be adjusted remotely using the Hydro-Com software to minimise the effects of noise of the measured signal. Advanced Digital Signal Processing provides a clear signal with a rapid response.

- Measurement Modes

- Choice of measurement modes for optimising sensor performance in a variety of applications and material types (except Hydro-Probe).

- Fully Temperature Compensated Measurement

- The sensor internally adjusts for mechanical changes due to temperature fluctuations

- Easy to Interface

- Two analogue outputs and digital RS485 communications and configurable digital inputs / output make the sensor simple to integrate into a control system. Includes Modbus.

- Fast Measurement

- Measuring at 25 times per second, the sensor continuously detects changes in the moisture of the materials throughout processing.

- Temperature Measurement

- Temperature output is available to provide a readout of material temperature.

- Accuracy of Measurement

- All measurements can be calibrated to an accuracy of 0.2% for aggregates (0.1% in the mixer) and 0.5% for other materials.

- Sensor Configuration

- Sensors can be remotely configured using Hydro-Com diagnostic software or Hydro-View/Hydro-Hub. All readings and sensor parameters are available including the type of output and filtering characteristics.

- Calibration

- The sensor may be internally calibrated using Hydro-Com software, or the linear output may be calibrated within the control system or remotely by using the Hydronix Hydro-View/Hydro-Hub interfaces.

- Simple Power Requirements

- The sensor may be powered from a 15-30V dc supply. Multiple sensors may be driven from a single power source.

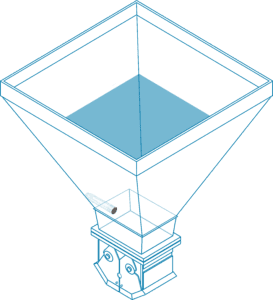

0310 Thermo-Tuff Mounting Collar

0310 Thermo-Tuff Mounting Collar 0320 Thermo-Tuff Extension Mounting Sleeve

0320 Thermo-Tuff Extension Mounting Sleeve