Rice Processing Moisture Measurement

Measuring moisture during the processing of rice is recommended in several places, including raw material intake, conditioning, drying, finishing, and packaging. Moisture control contributes directly to delivering a consistent final product and allows energy optimisation.

Typical Applications

Typical Materials

- Rice

- Paddy rice

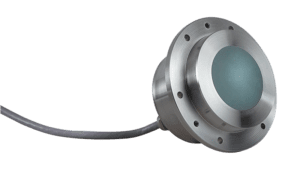

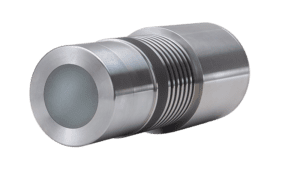

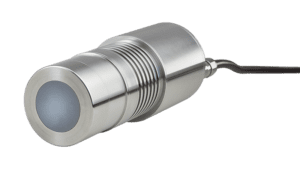

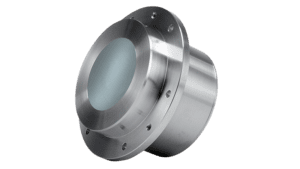

Related Products

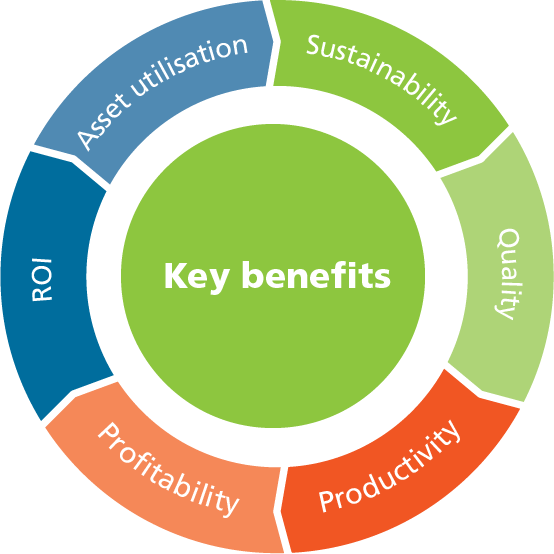

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Videos

Why Should I Care about Moisture?

Edited 14 February 2024 Benefits of Measuring Moisture in Grain Processing Recent advances in moisture measurement technology are enabling forward-thinking businesses to achieve better control of their grain processing operations,…

Read more

Moisture Measurement in Rice Production

Increasing Product Quality and Yield While Reducing Energy Costs India is the second-largest producer of rice in the World, second only to China, and processing approximately 155.682 million metric tons…

Read more