The importance of moisture measurement and control throughout the flour milling process

1. Summary

The moisture in grain is critical to the flour milling process. This article will describe how to control moisture levels in the material and outline the benefits moisture control delivers in terms of quality, environmental impact, and profitability of the final product.

2. Introduction

Grain is a natural product, so the moisture in the bulk material varies due to several factors, including different growing conditions, weather conditions during harvest, the threshing operation, and post-harvest storage conditions.

After harvest, industrially processed grain is often handled in a mill where it is flaked, rolled or ground into flour.

Moisture levels are a critical factor throughout the mill because they affect machinery performance, material plasticity or malleability, and final product quality. Also, achieving the correct moisture content of the final product is important to prevent premature spoilage and a short shelf life.

By measuring and controlling the water content of the material at each step of the milling process, it is possible to improve efficiency, reduce energy consumption, and save money.

Consistent moisture control also enables a miller to achieve higher yields of better quality with less waste.

3. Where to Measure?

The main process measurement locations that deliver the best returns on investment are outlined in this section.

3.1 Raw Material Intake

By measuring moisture in the incoming material, it is possible to ensure that wet material does not contaminate the storage silos. If wet material is detected, it is either rejected at source or managed, either by drying or by storing wet material in a silo with drier material and allowing the silo environment to balance the moisture levels.

3.2 Raw Material Drying

When wet material flows through an intake, one moisture management option is to dry the material before storing it.

Managing the drying process is vital because under-drying in storage silos will cause wet material to grow mould that creates hotspots that can lead to potentially catastrophic heat buildup and, eventually, explosions.

Therefore, it is crucial to remove only the excess water and not over-dry the material. If overdried, energy is wasted, causing additional costs, both financial and environmental. If grain is stored too dry it can also create other hazards, such as excess dust that can also lead to a combustive mix. If not corrected by further conditioning prior to milling it will also reduce yields.

3.3 Transfer

Knowing the moisture content during all grain transfers is important, either as a preventative measure to avoid spoilage in storage silos, as a quality control check, or to provide useful measurements for controlling the current or next processing stage.

3.4 Conditioning

When processing grain, moisture control is critical for product quality in several stages. This is achieved by introducing either a drying stage or a water addition stage before the process. It can also include a storage stabilisation stage to allow moisture to be correctly absorbed by the material so that it becomes homogenous.

3.5 Milling

Prior to milling, it is essential to control the water content of the source material, generally using a conditioning process as described in section 3.4.

The moisture in the conditioned material affects the size, durability, and ductility of the ground material, so measuring it online enables the milling system to adjust continuously to achieve the correct moisture content for efficient milling.

3.6 Post Milling

For process plants where milled flour is then being processed further into products, it is also critical to measure moisture during other process steps, such as mixing, kneading, extruding, and packaging.

4. Measuring Moisture

4.1 Why Measure Moisture?

There are several ways to measure the moisture of a bulk flow of material. The simplest and most common method is to take a sample of the material from the flow and then test the material’s moisture content in a laboratory.

This method often takes a lot of time to correctly process the test and will only be accurate for that small material sample of material at the specific time it was sampled.

Continually measuring moisture online is more accurate and enables operators and control systems to react quickly to changes in the material that could be detrimental to its milling efficacy or storage quality.

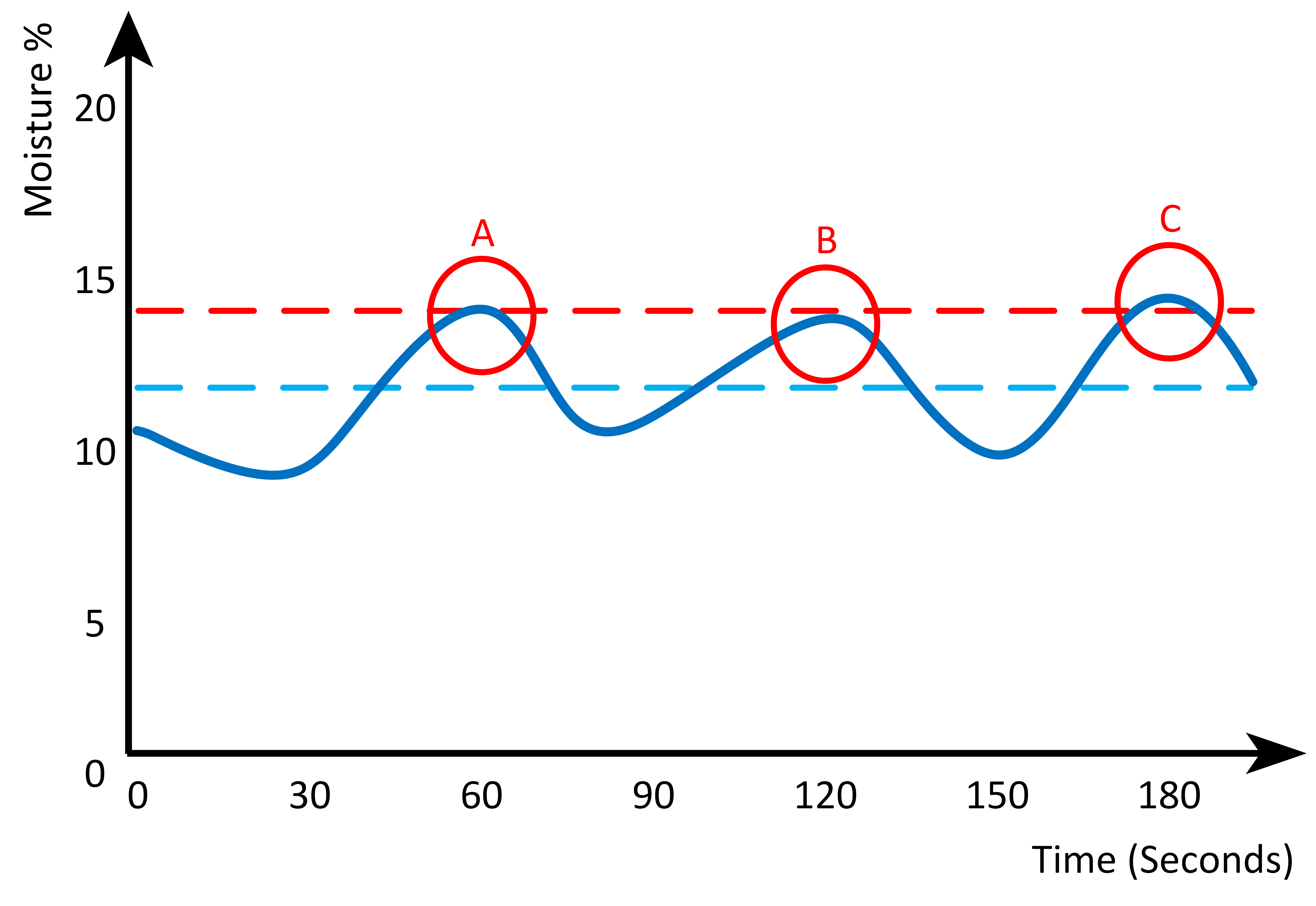

For example, raw grain from a farm might vary in moisture content between 19% and 25%. If a real-time measurement of the moisture content was recorded, a graph similar to that in the following figure could be created:

If three samples of material were taken at the points shown with red circles, the average of the three samples would be approximately 24%.

Measurement online allows the full signal to be averaged, rather than an average of specific points, so that all of the real-time data is included for a far mor precise measurement. In the example, the actual average of the flow is 22% so a 2% error in the sample average is evident. As discussed later, this can have a large impact on the yield of the dryer and also the energy consumed.

4.2 Real-Time Measurement

There are several types of sensing technology that is used to achieve this, each with their own distinct characteristics and benefits.

4.2.1 Near Infra-Red

NIR sensors tend to have higher installation costs and ongoing maintenance charges to give correct performance.

These costs can be offset against the ability to get additional, useful, online measurements from the sensor, such as protein and fat content, amongst others, which can be beneficial for controlling the quality and consistency of the formulation.

As an NIR sensor performs an optical measurement, it will be affected by changes to the material colour caused by dust and ambient temperature. An NIR sensor will only measure the surface moisture and not penetrate the material’s volume flow.

4.2.2 Resistive/Capacitance

Resistive and capacitive sensors both use electromagnetic waves at low frequencies to determine the electrical properties of the material. They are often very low-cost. However, they can be affected by salts, density changes, and temperature, making them overly sensitive to any changes in the material and less precise than other techniques.

4.2.3 Analogue Microwave

Analogue microwave sensors use analogue measurement techniques to measure signal loss caused by the amount of water in the material. Analogue Microwave sensors are non-linear due to their method of measurement and are also affected by temperature, salt, and density changes. This makes them difficult to calibrate and, with normal environmental fluctuations, the repeatability of measurement results is poorer than other methods.

4.2.4 Nuclear

Nuclear sensors are expensive. While they provide an accurate measurement, due to their penetrative power, the measurement is typically of a large volume of space, which is unsuitable for smaller ducts or conveyors. They also need regular, expensive maintenance by specifically qualified and certified personnel.

4.2.5 Digital Microwave

Digital Microwave sensors use a specific linear measurement technique, measuring signal frequency shift (often as well as the signal loss) caused by moisture content changes in the material. They are very stable over time and with temperature changes, which makes them simple to install, calibrate, maintain, and use. However, they require a good, consistent flow of material within which to measure, but the mechanical design of the flow mechanisms can usually ensure this.

5. Case Study

5.1 Process Control

Manually controlling a process has many potential difficulties. Operator reliability and performance can vary, and the slow feedback limits the precision of control to around +/-1% in the best systems.

If sensors are installed into a dryer to control dryer temperature, an optimal control accuracy of +/-0.5% of the final absolute material moisture target can be achieved in many materials. This accuracy is limited by the accuracy of the lab-based moisture content determination method used to check the sensor rather than the sensing technology itself.

It is possible to calculate the theoretical power input into a dryer to compare the difference in performance between the two measurement systems:

- Manual Control – With a manual system that can control to +/-1%, a dryer with incoming material at 20% moisture that has a final target of 13% must target 12% to ensure that the required amount of moisture is removed. This is a removal of 8% water by weight, and this will take 45.9 kWh of energy per metric ton of material in the dryer.

- Automated Control – If a process moisture can then be controlled using an online measurement, and an accuracy of +/-0.5% can be used, then a target value of 12.5% can be used. This is then a removal of 7.5% moisture which reduces the energy input, in a perfect system, of 42.6kW/t, a reduction of 7%!

If the natural energy losses in a dryer are included, then the savings can be greater.

A reduction in energy input also results in a corresponding reduction in the environmental impact of the material as energy results in emissions (in the UK energy market) of 0.193kgCO2e/kWh. Taking that into account, processing a 16-tonne batch of grain with online moisture control would reduce the environmental impact by more than 10kgCO2e in environmental impact (as well as GBP15.84 in energy cost).

Another benefit of good moisture control is that by being able to precisely target the final moisture content, it is possible to maximise yield. A 16-tonne batch of product that is produced which has 16.5% moisture has 80kg of extra weight than a batch which is produced with 16%.

During a case study, a Hydronix customer also reported that in a rice mill, they added moisture control to their dryer which enabled them to reduce their broken rice by 2.5%, allowing them to produce an extra 400kg of product per 16-tonne batch.

6. Conclusion

Measuring online allows for an immediate reaction to moisture changes, allowing real-time control of a process. Real-time moisture control also benefits producers from higher yield, energy savings, and consistent product quality.

By optimising the processes, the environmental impact of the final product can also be decreased, and adding moisture sensors to existing systems is a very straightforward way to get a high return on the investment.