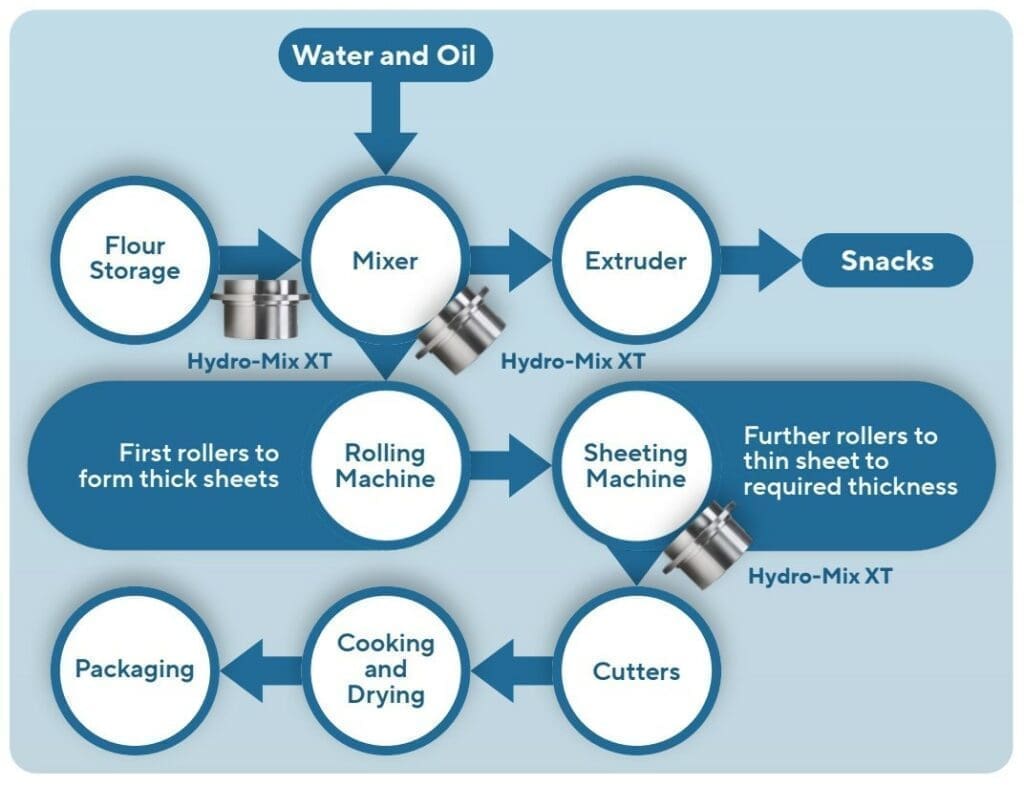

Benefits of moisture control in wheat flour noodle processing

Noodles are made from wheat flour which are then dried, shaped and packaged, for example, as instant noodles. In the beginning steps, water is present and could lead to problems such as dough clogging the machines, quality issues, or, even worse, downtime for the plant.

Controlling the moisture becomes vital, and the Hydro-Mix XT is installed inline in the process (an explosive atmosphere version is also available). It provides instantaneous feedback to the control system to reach the

correct moisture targets.

Benefits of measuring moisture in the noodle processing:

- Ensure the dough is the correct moisture to be worked with. Too wet and it becomes sticky, too dry and it crumbles.

- Calculate the correct amount of water to add to the flour.

- Mix the dough homogenously.

- Check dough is at a suitable moisture to be used by the rolling machine.

- Provides a final QA check that the dough sheet is at optimum moisture content.

Where to measure moisture?

Typically, there are 3 places to install a moisture sensor:

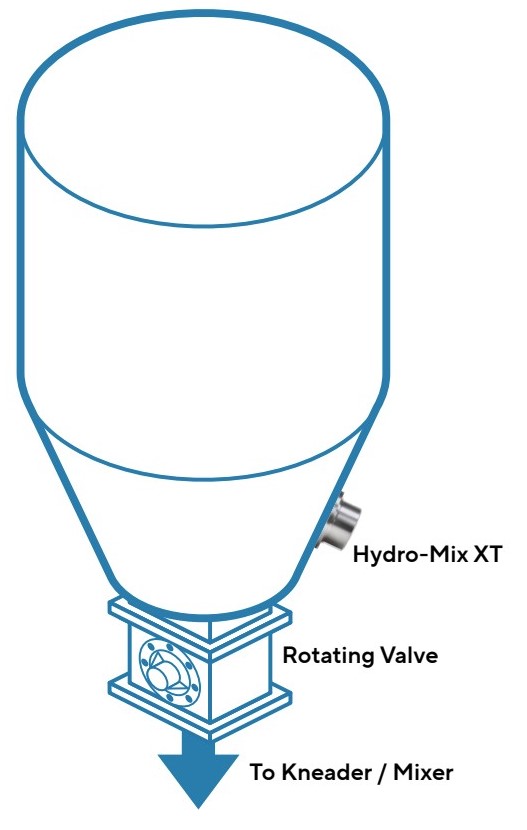

1. In the flour hopper prior to the mixer:

The flour hopper is typically designed to prevent build-up on the hopper walls, so a sensor with a flat profile, such as the Hydro-Mix XT, is suitable.

The sensor is built with an averaging function which can determine the moisture of the batch when the hopper is discharged.

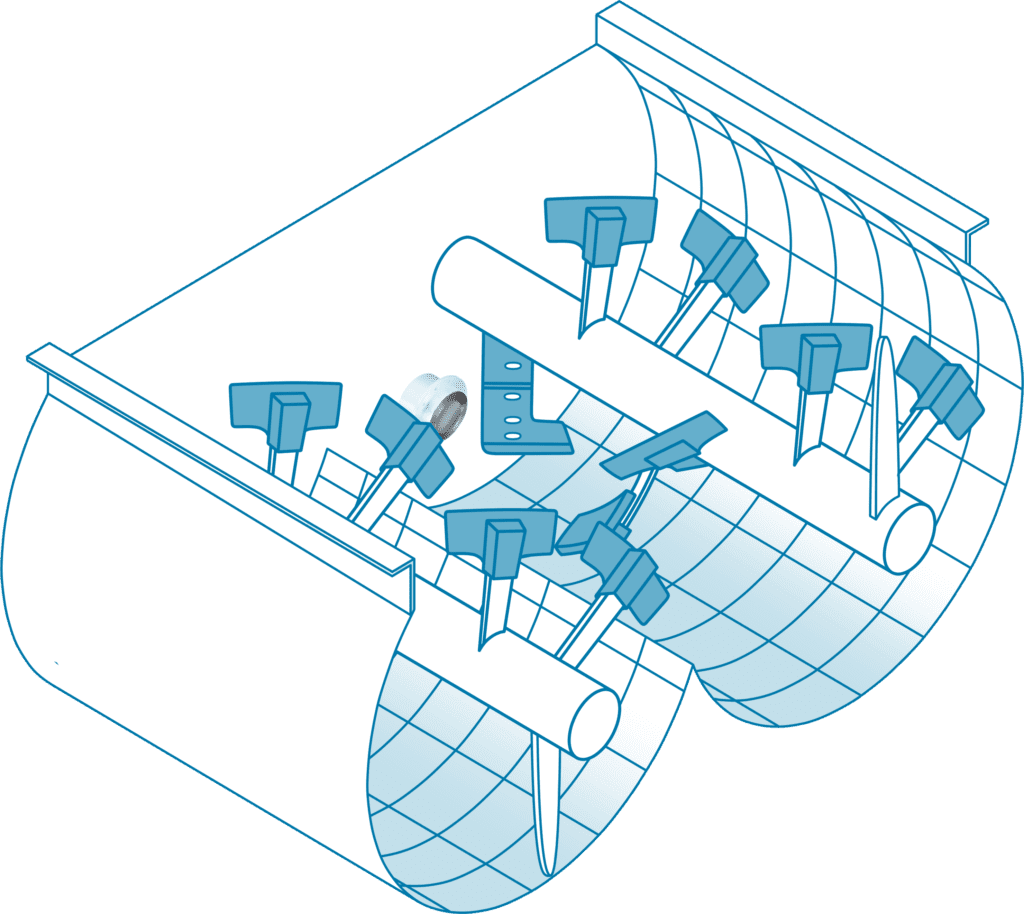

2. In the mixer

The material is dosed in from the flour hopper, and the moisture content is measured at the end of the dry mixing time. Knowing the initial moisture level, the sensor can provide feedback to the control system and allow the correct amount of water to be added.

Water is added to the mixer, and a wet mix is performed before the material is ready to be emptied into a rolling machine or extruder.

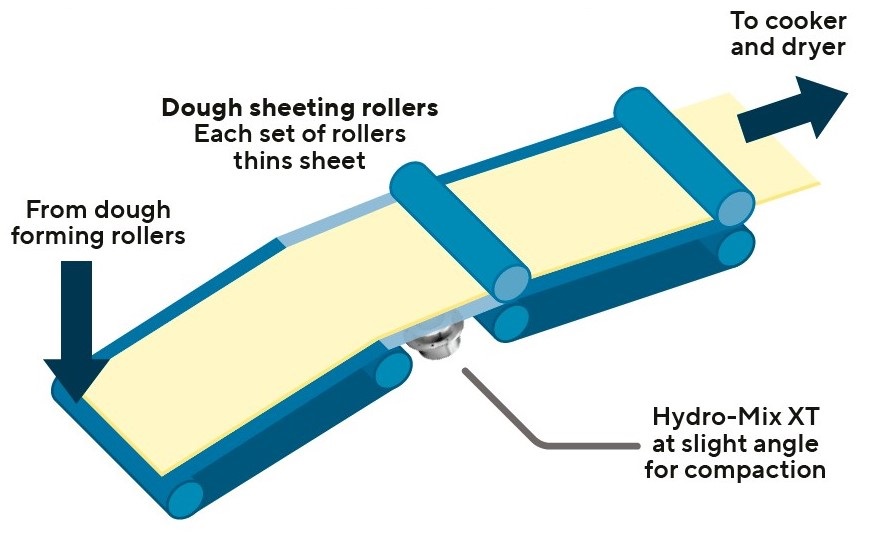

3. After the first set of rollers

After the dough has been formed into a sheet, a Hydo-Mix XT can be installed after the first roller. The sensor value at this stage is used as an input to the cooking and drying process that follows.

Expected Accuracy

A Hydro-Mix XT is installed in the end wall of the mixer. It is expected the accuracy will be better than :

- Hoppers ±0.5%

- Mixer ±0.2%

- After Rollers ±0.5%

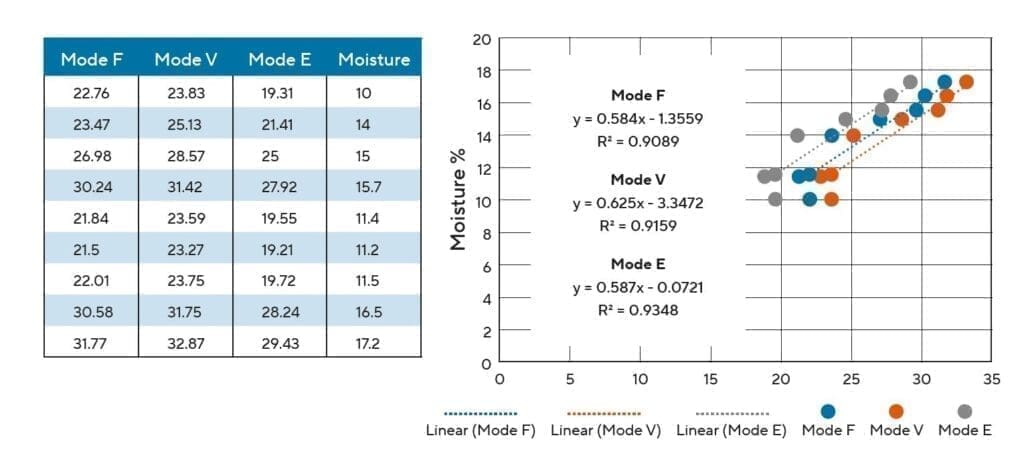

Calibration data from the hopper and after the first set of rollers:

Hydro-Mix XT-EX

The Hydro-Mix XT-EX has been designed to measure moisture in flowing bulk solids such as animal feed, grain, rice, pulses, and liquids in an explosive dust environment. The sensor can be easily installed in ducting, conveying, and mixing systems. It is suitable for Zone 20 process environments (Zone 21 external to process).

Comprising a single, intelligent unit that contains all on-board functionality, including signal processing and averaging, the Hydro-Mix XT-EX precisely measures the moisture content of material passing over the ceramic faceplate.

The Hydro-Mix XT-EX can be mounted in many different locations where there is a continuous flow of material across the ceramic faceplate. These include hoppers, ducting, conveyors, and mixer systems.

Conclusion

During noodle processing, it is crucial to control the moisture in order to obtain a homogenous, high-quality dough that will not crumble or be too sticky. By adding moisture measurement in 3 critical areas, it is possible to cover the entire process and provide complete end-to-end moisture control.

Hydronix has a range of moisture sensors with high precision and accuracy, which can be used in the process. The Hydro-Mix XT-EX will specifically help with the installation into an explosive dust environment, whereas the Hydro-Mix XT can be used in ordinary locations.