Controlling Moisture in Dried Sugar Beet Pulp

The increasing cost of inputs such as raw materials, energy and labour are forcing sugar beet processors to look more closely at controlling their overall cost of production. A simple and cost effective way of making savings is to control the level of moisture in the material during processing. Developments in digital microwave moisture measurement now enable a high precision moisture sensor to be installed at the output of a dryer for a relatively low cost. This low cost of purchase, low cost of ownership and ease of use now ensure that adopting moisture measurement in the process is more appealing to plant operators than ever before.

The need to measure moisture

After extracting the sugar from the cossettes in the diffusion process, the wet pulp is pressed and dried to produce an Animal Feed by product. The drying process is extremely energy-intensive requiring the material to be sufficiently dry so that it can be easily pelletized without causing the machinery to jam or create brittle pellets.

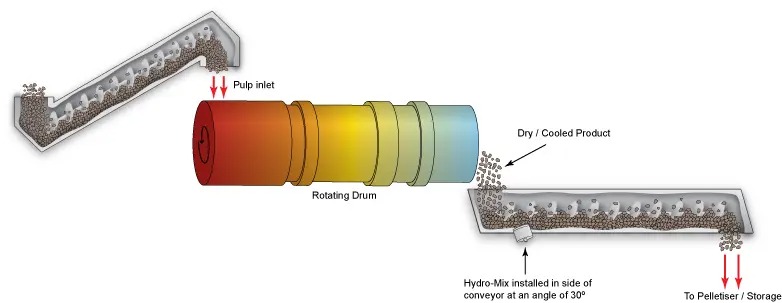

Pulp dryers can be in the form of direct-fired rotating drums, fluidised bed steam dryers or low-temperature belt dryers. The main objective, however, of any drying system is to reduce the moisture level in the material to between 10 and 12%.

Current off-line methods of testing for moisture such as oven tests are time-intensive and do not allow the dryer to be adjusted in real-time. A popular form of on-line measurement is an Infra-Red system. These tend to be expensive and because they only take a surface measurement of the material may be subject to unrepresentative readings caused by flash drying of the upper layer of the dried pulp. Being a non-contact measurement they are also susceptible to dust in the environment and accumulated dust on the lens of the instrument causing erroneous readings. An automated system, using microwave sensors, can easily identify the moisture in all of the material as it leaves the dryer providing instant information to the control system. This allows the temperature / drying time/speed through the dryer to be adjusted accordingly, ensuring the exiting material is always at the correct moisture level ready for the pelletizer or for storage.

The benefits of installing Hydronix microwave moisture measurement sensors

- Dryers can be used more efficiently thereby reducing energy costs

- Improved and consistent final product

- Reduction in level of spoilt / wasted materials

- Not affected by dust or colour

Recommended installation

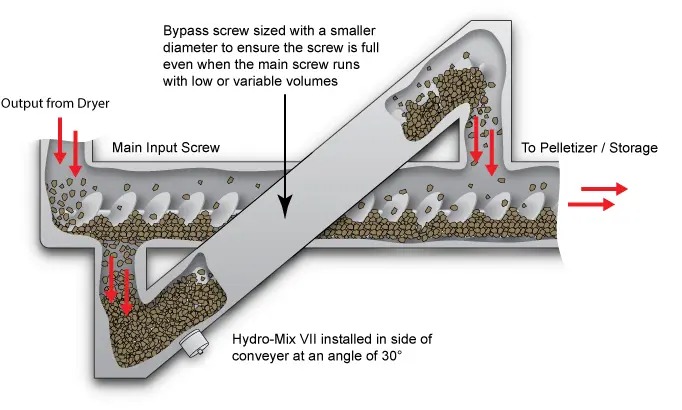

Installation of the sensor is dependent on the application. There are two main installation methods. One is for applications that have a consistent flow rate and where the screw is always full, the other is for installations that have a variable flow rate and where the screw may be only partially full. These installations require the use of a bypass system to ensure a consistent material compaction and flow across the sensor.

Result after installing the sensors

A well implemented installation will measure the moisture levels of the materials exiting the dryer to an accuracy of +/- 0.5% enabling the dryer to be controlled more precisely. Real time control of the dryer, as opposed to waiting for oven tests, ensures that the dryer is controlled instantaneously resulting in increased energy efficiency. There is also a reduction in the amount of substandard or wasted product caused by the time delay between periodic sampling and subsequent dryer adjustment.

Hydro-Mix XT sensors

Hydro-Mix XT sensors are constructed of hardened stainless steel and have an abrasion-proof ceramic measuring faceplate. Because the sensor is designed to be installed flush-mounted with the surface it allows the material to flow freely over the measuring faceplate without causing any build-up.

Conclusion

The inclusion of a microwave moisture measurement system into the existing process will not only achieve consistent quality products while reducing the amount of spoilt materials but also provide instant savings and repay its capital expenditure in a very short time.